Pipe Repair Equipment

Hub City Iron Works provides a variety of equipment centered around repairing or preventing damage to your pipe.

Lathe Refacing Machine

The Hub City Iron Works Lathe Refacing Machine is used to repair the face and adjacent bevel of tubular goods. Its innovative design utilizes a mandrel to maintain exact orientation while performing the refacing operation. Another advantage of the Refacing Machine is the ability to perform refacing operations in the field or inspection facility, saving trucking and machine shop costs.

Hardbanding Application Unit

Hub City Iron Works Hardbanding Application Unit is a production oriented machine used to apply hardfacing material to pipe according to industry standards. Some of the key features of the Hardbanding Unit include powered V-Rollers to simplify loading and automated band application, which ensures a consistent process. The unit utilizes industrial grade welding equipment and ultimately enables a consistent and quality hardbanding application to be performed in a safe and efficient manner.

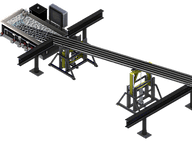

Phosphate Dip System

Hub City Iron Works Phosphate Dip System is designed to safely and efficiently phosphate pipe connections. It functions by raising one end of the pipe with a lift and dipping the other into a phosphate reservoir. In addition to being cleaner and more environmentally friendly than spray systems, the Phosphate Dip System is also easier to maintain as there are no nozzles to stop up and surrounding equipment is not damaged by overspray. When equipped with the optional pipe turn around, phosphate operations can be done to both connections without the need to manually reorient the pipe.

Pipe Straightening Machine

The Hub City Iron Works PSM is a ram-type Pipe Straightening Machine that is available as a self-contained skid-mounted unit, a stationary unit for permanent plant installations or a portable trailer-mounted unit. With capacity options ranging from 75-Ton to 250-Ton, the PSM can straighten any standard oilfield tubular.